Lassi, the creamy, classic Indian yogurt drink, is experiencing a global renaissance. For restaurants, hotels, catering services, and large sweet shops, meeting this escalating demand while maintaining quality is a major challenge. The Texture, Test - Mouth-watering, Life of product, Physical appearance Thickness.

Manual churning is slow, labour-intensive, and rarely yields a perfectly consistent product. The solution? The Automatic Lassi Making Machine—a piece of commercial kitchen equipment that is revolutionizing dairy processing in the food service industry.

This ultimate guide will explore the function, features, and financial benefits of investing in a high-volume lassi maker for your business; which made customise for particular requirements.

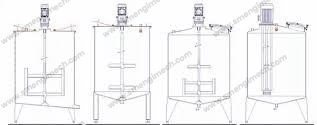

Often referred to as a Commercial Curd Churner or Electric Percolator, this robust machine automates the process of transforming curd (dahi /yogurt) into a smooth, frothy lassi or buttermilk.

| Feature | Manual Process | Automatic Machine Process |

|---|---|---|

| Speed | Slow, varies by person | High-speed, consistent cycle time / Variable drive also available |

| Consistency | Highly variable texture | Uniform blend and perfect froth |

| Capacity | Small, batch-by-batch | Large capacity (20L, 50L, 100L, 500+) |

| Versatility | Limited to churning | Can also make buttermilk (chhaach) and nowadays helps in butter separation to make Desi Ghee |

The best models are considered both Dairy Equipment and essential Commercial Kitchen Machinery due to their specialized blending function for dairy products.

Investing in an Automatic Lassi Maker is not just an equipment upgrade—it’s a business strategy.

A high-speed automatic lassi maker drastically reduces production time.2 During peak hours, this translates directly into faster service, higher table turnover, and the ability to fulfil bulk orders (like for catering) without strain. You move from making lassi in minutes per glass to producing dozens of liters in a single, short cycle.

Consistency is the cornerstone of brand loyalty. Manual churning introduces variability. An automatic machine, with its powerful motor and set timers, guarantees the perfect texture and ideal mix every single time, ensuring your famous sweet lassi, salty lassi, or mango lassi tastes exactly the same, day after day.

By automating the most time-consuming task of stirring and churning, you free up skilled labor. The machine requires minimal supervision, allowing your staff to focus on customer service, packaging, or other food preparation. This is a crucial factor in achieving lower operational costs and higher profit margins.

Food-grade standards are non-negotiable. Quality Commercial Lassi Machines are built using Stainless Steel (SS 304), which is:

These machines are not single-function devices as with Variable drive make it Multiple functions & usefulness in industries.. They are heavy-duty blenders perfect for creating:

Before purchasing your automatic curd churner, evaluate these key technical specifications:

| Feature | Why It Matters | Capacity Range |

|---|---|---|

| Capacity | Must match your peak service or batch requirement. | 10 LTR (Small Cafe), 20 LTR (Mid-Size Restaurant), 50 LTR+ (Catering/Industrial Production) |

| Material | Ensures hygiene and longevity. | SS 304 Grade Stainless Steel (Minimum requirement for food contact). |

| Motor Power | Determines blending speed and endurance. | Heavy-Duty Motor (often 0.5 HP or 3 HP for large models) with high RPM / Geared Motor available for low RPM thick materials. |

| Operation Type | Defines the level of manual intervention. | Fully Automatic (minimal staff time) or Semi-Automatic (more control). |

| Rinse/Drainage | Simplifies post-production clean-up; CIP. | Easy-access drainage valve for fast cleaning-in-place (CIP). |

The move from manual to Automatic Lassi Making Machine is the benchmark for modernization in the beverage and dairy sector. It’s an investment that pays dividends through higher throughput, reduced labour costs, and a reputation for consistent, quality products.

By choosing a durable, high-capacity, and food-grade stainless steel machine, you are positioning your business for higher profitability and sustainable growth.

Contact SM Engineering, today to find the perfect Commercial Lassi Maker capacity—from 20 Liters to 500 Liters—that fits your business needs and start churning out success! Also available all connecting container and accessories.