How Dairy Processing Plants Ensure Quality and Safety

By admin , JULY 12, 2025

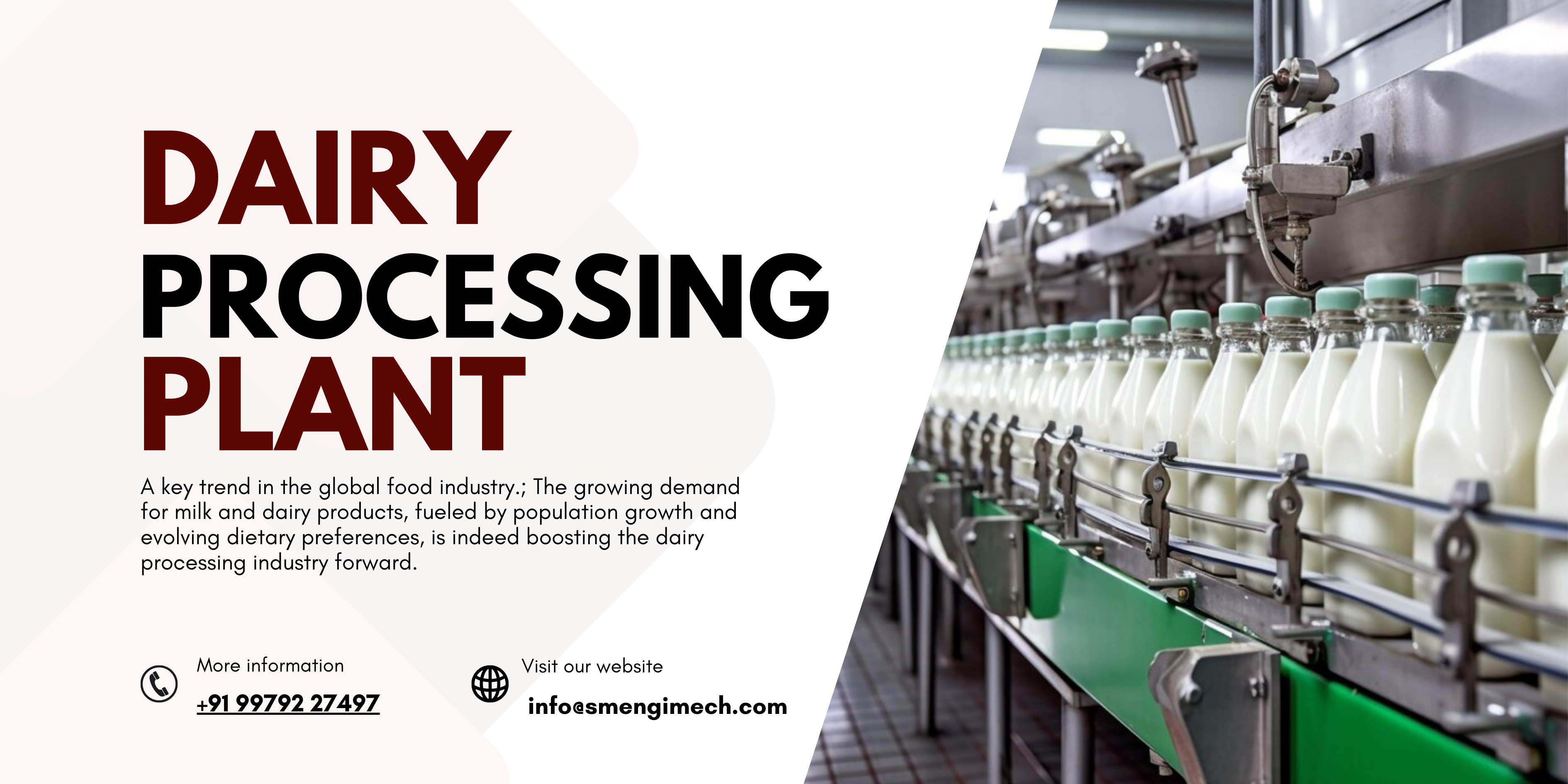

A key trend in the global food industry.; The growing demand for milk and dairy products, fueled by population growth and evolving dietary preferences, is indeed boosting the dairy processing industry forward. Increasing disposable income, Expanding dairy product range Growth in emerging markets

dairy processing plants cover various aspects, including the benefits of modernizing plants, automation, and the impact of technology on dairy product quality and safety. These blogs also delve into the different stages of dairy processing, from raw milk collection to packaging, and explore the production of various dairy products like cheese, yogurt, and ice cream.

Revolution in dairy product advance has created new and exciting options for consumers, driving demand. processing industry to new heights. Dairy Processing Plant Manufacturer SM Engineering , thanks to their extensive knowledge and years of expertise in the field.

If you're looking to streamline and simplify your dairy operations, go no further than SM Engineering, a leading dairy plant machinery manufacturer. We oversee the whole lifecycle of your dairy project, from initial ideation to final commissioning, drawing on our wealth of knowledge and experience in the field to guarantee a faultless operation that lives up to your expectations. Advanced dairy processing technologies and efficient production methods to meet consumer expectations.

Key Focuses Initiate In Dairy Processing Plant:

Plant Innovation and Automation: Benefits of Automation: automation streamlines operations, reduces labor costs, and minimizes waste in dairy processing plants. Increase Efficiency.

Plant Innovation and Automation: Benefits of Automation: automation streamlines operations, reduces labor costs, and minimizes waste in dairy processing plants. Increase Efficiency.

Technological Innovations: Technologies are shaping the industry, including cutting-edge heat treatments, pasteurization, and homogenization processes.

Technological Innovations: Technologies are shaping the industry, including cutting-edge heat treatments, pasteurization, and homogenization processes.  Impact on Dairy Industry: Dairy products are processed and packaged, improving efficiency and product quality.

Impact on Dairy Industry: Dairy products are processed and packaged, improving efficiency and product quality.  Dairy Product Processing: Stages of dairy processing, such as milk collection, heat treatments (pasteurization and sterilization), homogenization, and packaging.

Dairy Product Processing: Stages of dairy processing, such as milk collection, heat treatments (pasteurization and sterilization), homogenization, and packaging.  Production of Various Dairy Products: Making Paneer, cheese, yogurt, ice cream, and dairy products Sweets.

Production of Various Dairy Products: Making Paneer, cheese, yogurt, ice cream, and dairy products Sweets.  Quality and Safety: Significance of maintaining high standards for dairy product quality and safety through proper processing techniques and observance to regulations.

Quality and Safety: Significance of maintaining high standards for dairy product quality and safety through proper processing techniques and observance to regulations.  Specific Equipment and Processes & Pasteurization and Sterilization:

methods of pasteurization and their impact on milk safety and shelf life.

Specific Equipment and Processes & Pasteurization and Sterilization:

methods of pasteurization and their impact on milk safety and shelf life.

Homogenization: In achieving a uniform texture and appealing appearance of dairy products.

Homogenization: In achieving a uniform texture and appealing appearance of dairy products.

CIP Systems: The importance of Clean-in-Place (CIP) systems for maintaining hygiene and sanitation in dairy processing plants.

CIP Systems: The importance of Clean-in-Place (CIP) systems for maintaining hygiene and sanitation in dairy processing plants.

Floor Drainage: proper floor drainage systems in dairy processing plants to prevent bacterial growth and a safe Environment.

Floor Drainage: proper floor drainage systems in dairy processing plants to prevent bacterial growth and a safe Environment.

Business and Industry Insights: Starting a Dairy Processing Business: Tainting program by SM Engineering; How to start a dairy processing venture, including considerations for equipment, production, and market reach.

Business and Industry Insights: Starting a Dairy Processing Business: Tainting program by SM Engineering; How to start a dairy processing venture, including considerations for equipment, production, and market reach.